1974 Bolwell Mk VIII Nagari

Country of Origin: Australia

Design Info: A lightweight, front-engined, rear-wheel drive fiberglass-bodied coupe (or occasionally roadster). The body, based somewhat on the previous Bolwell Mk VII, was styled with elements of the Lamborghini Miura, Lotus Europa, and Jaguar E-Type. Vents behind the front fender were necessary to help cool the cramped engine compartment. The car’s suspension was a mixture of Ford and bespoke parts, and while the backbone frame shared many similarities with the Lotus Elan, it was a completely original design based on locally produced components.

Engine Info: Originally designed for a Holden V8, early cars received a Ford 302 Windsor, but later Bolwell Nagaris were actually built with either the Australian market Ford 302 Cleveland or with the 351 Cleveland. The large size of even the 302 Cleveland, which unlike Windsors was based upon the 351 block, necessitated some creative solutions to fitting the engine in the car, such as repositioning the exhaust manifolds and having them blow forward instead of back. The heavy engine was mounted so far back that the flywheel and clutch sat behind the windshield. The Windsor Nagaris could complete a quarter mile in 14.8 seconds and reach a top speed of around 130 mph. The 351 units were significantly quicker, and feature a distinct hood bulge to accommodate the larger engine.

Type: A two-seat sports car, the Bolwell was often compared to contemporaries like the Lotus Elan, Datsun 240Z, Jaguar E-Type, and the Chevrolet Corvette, as well as some earlier sports cars like the Shelby Cobra and TVR Griffith.

History: Campbell Bolwell, the middle of three brothers, bought a 1937 Ford sedan when he was 16. His younger brother, Graeme, ‘borrowed’ the car for a joy ride with some friends. The disastrous result of their drive left the car ‘unrecognizable’ in Campbell’s words.

Rather than try to buy a new car, Campbell began skipping his high school classes and worked on the car feverishly to get it back on the road. With the power of the flathead Ford and a lightweight clubman-style body, the Ford became a certifiable sports car, which the Bolwells would eventually call the MkI.

Not satisfied, Campbell dropped out of high school to build a better car. The MkII would be based on an MG chassis and ran a four-cylinder Ford which was more manageable. For the MkIII, both Campbell and his older brother Winston would build a pair of cars, this time mating Jaguar engines to Austin-Healey chassis, and together the brothers worked on fiberglass bodies, still a fairly new technology in automotives at the time. In 1963, while Bruce Meyers was still working on his prototype for the Meyers Manx buggy, the Bolwell brothers began selling the Bolwell MkIV fiberglass-bodied kit car.

The MarkV and VII followed (as well as an attempt at a production race car, the SR6), largely using Holden mechanicals and engines. Graeme moved to England to work for Colin Chapman at Lotus, while Campbell and Winston continued to work at perfecting fiberglass construction techniques. Campbell had begun to worry about the company name—his name—being seen on kit cars whose quality of construction was at the mercy of the customers that built them. Graeme, likewise, was present at Lotus when Chapman had begun turning Lotus away from the kit car business model. When, six months later, Graeme returned to the brothers’ company, the three brothers, and their neighbor, Ross McConnell (who, as of 2019, continued to work for Bolwell despite his official retirement) decided to design a new car for turnkey sales, moving Bolwell from kit car producer to auto manufacturer.

While the styling for the MkVIII was a team effort, Campbell gives a lot of credit to his brother Winston, who aside from his work in fiberglass taught gold and silver smithing. The flowing, sleek lines of the car gave rise to the name “Nagari”, an Aboriginal Australian word that translates to “flowing”. Sadly, Winston would be killed in a car accident prior to the release of the Nagari.

The mechanicals of the car would prove difficult to manage in some ways. The recent Bolwell kit cars had been designed around the use of Holden V6s for power, and the brothers sought a supply of the new Holden V8 motor for this new car. Holden, however, was not willing to oblige. The new engine was still largely untested on the mass market, and the company was not keen to provide such a project to another company who they might then be liable to for design or manufacturing issues. The engine also represented something a status symbol for the company, and execs were not inclined to lessen this prestige by having their engine associated with a kit car.

Bolwell then approached Ford, who was happy to stick it to GM and everyone else by having their engines featured in nearly any high performance sports car or hot rod, and was able to secure a line on the Windsor 302, which was imported into Australia for use in some Falcons. Ford also assisted in suspension design by offering some parts which were locally manufactured, also for the Falcon. Unfortunately, around the time the Nagari went into production, Ford abruptly stopped importing Windsor 302s into Australia. Local production replaced them with a 302 based on the larger 335 series engine, which was commonly called the 351 Cleveland.

As the originally intended Windsor already barely fit into the car, the larger and heavier unit required some intense finagling to make it work. The engine was pushed even further back into the car, nearly right into the passenger cabin, making it more cramped and extremely hot. The engine exhaust had no room to exit at the rear (due to the backbone frame’s Y shape) and instead had to be modified and remounted to exit at the front of the engine. The heavier engine also worsened the car’s already somewhat precarious weight distribution. Between a lot of body flex and the propensity for the rear of the car to bounce because of its light weight, handling could be scary and even dangerous. While for track use, the suspension could be screwed down tight to alleviate these issues, the rough Australian roads made this nearly impossible for street use.

While the Nagari was developed and improved over its run, by 1974 the design was getting long in the tooth. Pressure to crash test the car, something Bolwell couldn’t afford to do, was mounting, as were production costs. The car was never cheap to begin with, its price significantly above most of its competitors. Holden and Ford muscle cars like the Monaro and Falcon could be bought for $1000 to $1500 less, even in their top trims, as could the Datsun 240Z. By 1974, the roadster variant of the Nagari was only about $1000 less than a Jaguar E-Type, with the coupe only slightly cheaper. Compared to these polished, corporate projects, the Nagari was still considered far too unrefined my the majority of the public to really be considered at a similar price. Attempt to export the car to Asian, African, and American markets failed, and so the brothers ended production.

Bolwell lived on, however. The expertise they had gained from working with fiberglass construction allowed them to profit on making everything from semi-truck bodies and lawn furniture to turbine blades and flight simulator shells. Bolwell would return to the kit car market in 1979 with the Volkswagen-based Ikara, and in the 2000s revived the Nagari name with the Toyota-powered Nagari 300 and the LS-powered Nagari 500. Whether more than a handful of these modern Nagaris are ever built remains uncertain, but the Bolwell company should at least have the technical know-how to back up their plans.

Why it’s cool/unique/significant: The Bolwell Nagari is a rare beast, a successful car designed and built by a few men in a workshop. While production and sales were certainly not astronomical (118 turnkey cars and an uncertain number of kits) it was enough to keep the company afloat. Unlike a lot of stories about car like this, in which poor luck or bad business practices cause the passion to bankrupt those involved, Bolwell continues on as a company, even if not as a full-on manufacturer of cars.

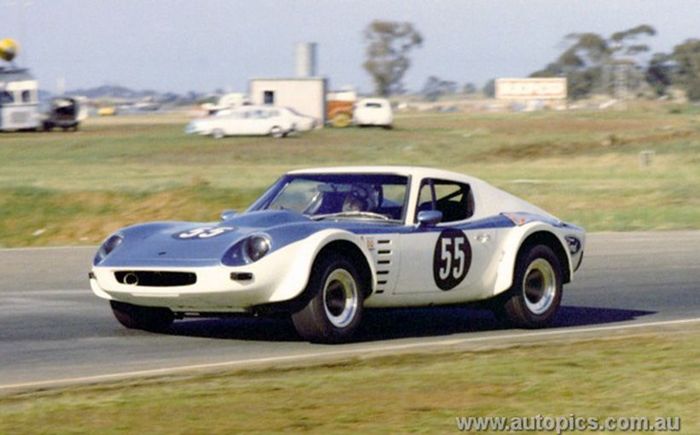

Beyond overcoming the common hurdles of small auto manufacturers, the Nagari also has some racing credit of its own. Nagaris were raced in the Australian Sports Car Championship in the early 70s against the likes of Allan Moffat’s Falcons and Peter Brock’s Holden Dealer Team, and while the Nagari never won outright against what were essentially purpose-built racing cars, in 1974 driver John Latham managed a 7th place championship finish, putting him at 1st place among production cars. The following year, a driver named Peter Warren won 1st place at Mount Panorama during the Australian Tourist Trophy also driving a Nagari. The Nagari was also very popular at other small events across Australia. Even though it is little known today, there is an argument to be made that the Bolwell Nagari might have been the greatest indigenous sports car ever made in Australia.